Volumetric depositors ensure consistent portion control and precision in the automated dispensing of food products,

enhancing production efficiency and maintaining quality standards.

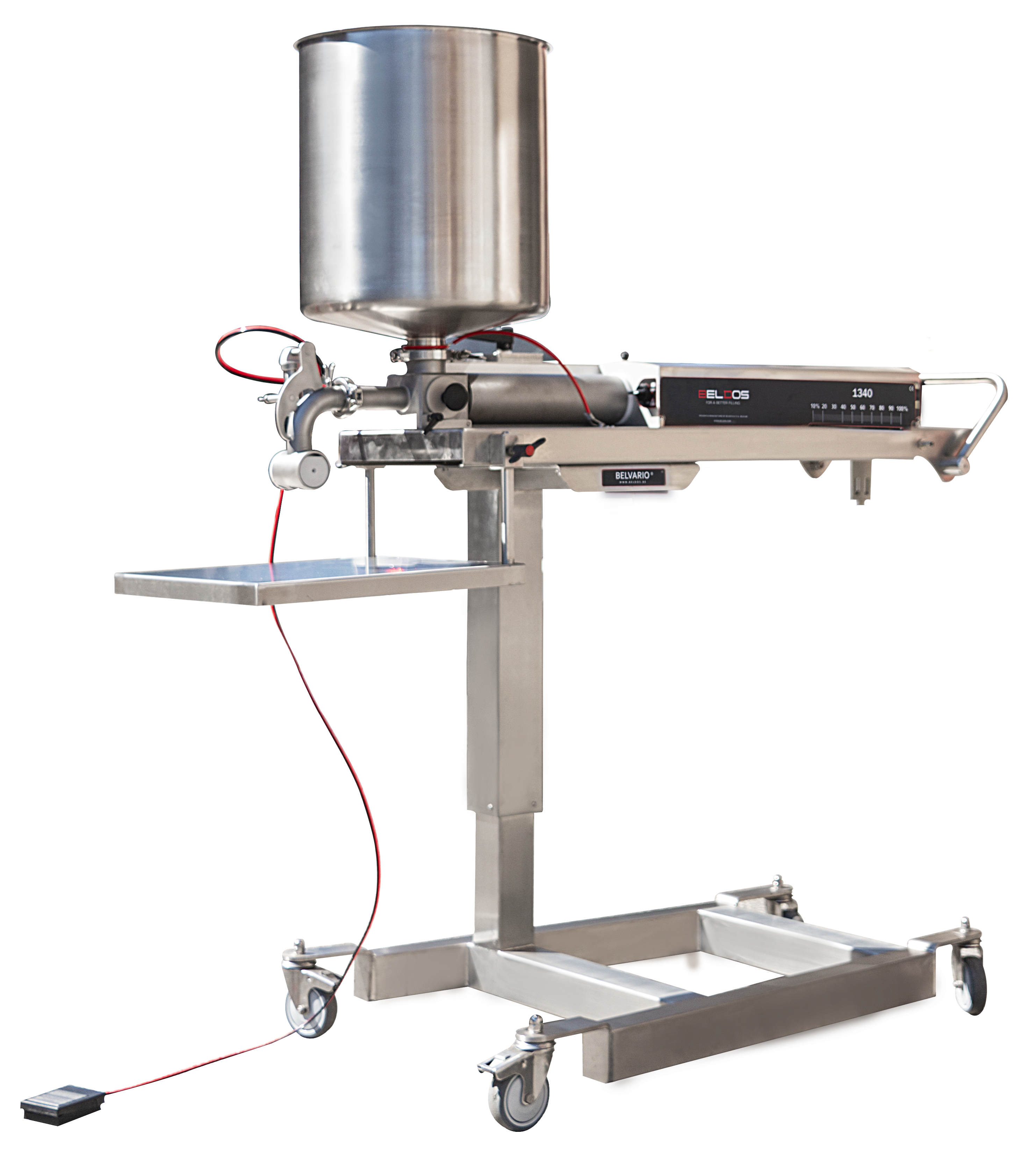

Volumetric Depositors, Fillers, Injectors and Decorators in Food Production

At Depositor Solutions, we understand the importance of precision and efficiency in food production. That’s why we’re proud to offer a comprehensive range of volumetric depositors, fillers, injectors and decorators for wet and dry portion production food manufacturing, designed to revolutionise your manufacturing processes.

With our cutting-edge technology and innovative features, depositors are engineered to deliver consistent results, streamline production, and elevate the quality of your products.

Key Features and Benefits

- Precision and Accuracy: Our volumetric depositors, fillers and injectors are equipped with state-of-the-art technology that ensures precise dispensing of ingredients, eliminating variations in portion sizes and product quality.

- Versatility: Whether you’re producing cookies, cake batters, pastries, or ready meals, our depositors offer unmatched versatility to handle a wide range of products and production requirements.

- Speed and Efficiency: By automating the depositing process, our depositors significantly increase production speed and efficiency, allowing you to meet high-demand scenarios without compromising on quality or deadlines.

- Hygiene and Cleanliness: We understand the importance of hygiene in food production. That’s why our depositors are designed with easy-to-clean surfaces and sanitary components, ensuring product integrity and minimising the risk of contamination.

- Customisation: Our depositors are fully customisable to suit your specific needs and production goals. From adjustable settings to interchangeable nozzles, we offer solutions tailored to your unique requirements.

Selection of our principle solutions for Volumetric Depositors, Fillers, Injectors and Decorators in Food Production

Common Questions on Volumetric Depositors, Fillers, Injectors and Decorators

Our volumetric depositors are advanced machines used in the food industry to dispense predetermined volumes of various types of ingredients accurately. From thick batters to delicate creams, volumetric depositors ensure precise portioning and filling, allowing manufacturers to maintain product consistency and meet consumer expectations.

Volumetric depositors operate by using a set volume chamber to measure and dispense exact amounts of product. This chamber fills with the product, and a piston or similar mechanism then pushes the measured amount out, ensuring uniformity.

Volumetric depositors can handle a wide range of products, including liquids, pastes, cake batters, creams, custards, jams and including solid ingredients, depending on the machine’s design and specifications.

Volumetric depositors are widely used in the food and beverage industry, particularly in producing baked goods, dairy products, sauces, spreads, and ready meals. They are also used in cosmetics and pharmaceuticals for precise product filling.

Yes, most modern volumetric depositors are designed with hygiene and ease of maintenance in mind. They typically feature parts that can be quickly disassembled and cleaned, complying with food safety standards.

Contact Us Today!

Contact us today to learn more about our range of volumetric depositors and how they can revolutionise your manufacturing processes.

Whether you’re a small bakery or a large-scale food manufacturer. We have the solutions you need to succeed in today’s competitive market.

Let us help you achieve your production goals and elevate the quality of your products with our advanced volumetric depositors.